Cooling Tower Components

Cooling fill type: CS 20 – foil fill

Characteristic:

Foil fill with innovative zigzag channels and unique surface design for highest thermal performance

Data:

- Type: CS 20

- Material: PVC / PP or others

- Channel width: 20 mm

- Foil connection: welded / glued

- Foil thickness before forming: 0.3 to 0.6 mm

- Length x width x height (package):

1,200 (to 3,000) mm 300 (to 600) mm x 400 mm - Max. temperature: 55°C (PVC) / 70°C (PP)

- Fire retardant: B2 according to DIN 4201-1 or ASTM E 84, FSI < 25

Special features:

- Best possible cooling performance with acceptable fouling-behaviour

- Further development of original Balcke-Duerr design

- unique approved design

- own manufacturing with original tools

The design is patented property of CTS:

- European patent no. 3 572 760 B1

- U.S. Pat. No. 11,175,097 B2

Cooling fill type: CS 30 – foil fill

Characteristic:

Foil fill with innovative zigzag channels and unique surface design for highest thermal performance and low fouling behaviour.

Data:

- Type: CS 30

- Material: PVC / PP or others

- Channel width: 30 mm

- Foil connection: welded / glued

- Foil thickness before forming: 0.3 to 0.6 mm

- Length x width x height (package):

1,200 (to 3,000) mm 300 (to 600) mm x 600 mm - Max. temperature: 55°C (PVC) / 70°C (PP)

- Fire retardant: B2 according to DIN 4201-1 or ASTM E 84, FSI < 25

Special features:

- Best possible cooling performance with good low fouling-behaviour

- Further development of original Balcke-Duerr design

- Lowest airside pressure drop in comparison to the high thermal performance

- unique approved design

- own manufacturing with original tools

The design is patented property of CTS:

- European patent no. 3 572 760 B1

- U.S. Pat. No. 11,175,097 B2

Cooling fill type: FB 20 – foil fill

Characteristic:

Foil fill with vertical offset channels for good thermal performance and low fouling behaviour.

Data:

- Type: FB 20

- Material: PVC / PP or others

- Channel width: 20 mm

- Foil connection: welded / glued

- Foil thickness before forming: 0.3 to 0.6 mm

- Length x width x height (package):

1,200 (to 3,000) mm 300 (to 600) mm x 300 or 600 mm

- Max. temperature: 55°C (PVC) / 70°C (PP)

- Fire retardant: B2 according to DIN 4201-1 or ASTM E 84, FSI < 25

Special features:

- Best combination of good cooling performance with good low fouling-behaviour

- Original Balcke-Duerr design

- World-wide unique and approved design

- own manufacturing with original tools

- better performing like market copies

Cooling fill type: FC 18 – foil fill

Characteristic:

Foil fill with throughout vertical channels for good thermal performance and lowest fouling behaviour.

Data:

- Typ: FC 18

- Material: PVC / PP or others

- Channel width: 18 mm

- Foil connection: welded / glued

- Foil thickness before forming: 0.3 to 0.6 mm

- Length x width x height (package):

1,200 (to 3,000) mm 300 (to 600) mm x 600 mm - Max. temperature: 55°C (PVC) / 70°C (PP)

- Fire retardant: B2 according to DIN 4201-1 or ASTM E 84, FSI < 25

Special features:

- Best combination of good cooling performance with lowest fouling-behaviour

- Original Balcke-Duerr design

- World-wide unique and approved design

- own manufacturing with original tools

- better performing like market copies

Cooling fill type – grid, inclined channels

Characteristic:

Grid fill with inclined channels for low fouling behaviour.

Data:

- Type: grid fill – inclined channels

- Material: PP

- Channel width: 20 mm

- Grid connection: mechanical

- Length x width x height (package):

910 mm x 600 mm x 450 mm – standard dimensions, other lengths and widths possible - Max. temperature: 70°C

- Fire retardant: B3 according to DIN 4201-1 is standard (B2 or ASTM E 84 on request)

Special features:

- Good combination of cooling performance with low fouling-behaviour

- Original GEA design

- Stable structural design – limited walkable on it

- Own design (performance tests & long-term experiences of cooling tower construction)

Cooling fill type– grid, vertical channels

Characteristic:

Grid fill with vertical channels for lowest fouling behaviour.

Data:

- Type: RG V2 – vertical channels

- Material: PP

- Channel width: 20 mm

- Grid connection: mechanical

- Length x width x height (package):

450 to 2700 mm x 300 mm x 450 mm - Max. temperature: 70°C

- Fire retardant: B3 according to DIN 4201-1 is standard (B2 on request)

Special features:

- Good combination of cooling performance with lowest fouling-behaviour

- Original Balcke-Duerr design

- Very stable structural design – walkable on it

- Own design (performance tests & long-term experiences of cooling tower construction)

Patented full cone nozzle

Data:

- Types: NS 32 & NS 50

- Flow rate NS 32: approx. 6 to 14 m³/hr (1.4 to 3.2 gpm)

- Flow rate NS 50: approx. 3 to 7 m³/hr (0.7 to 1.6 gpm)

- Pressure range NS 32 & NS 50: approx. 0.05 bar to 0.3 bar

- Material: PP

- Connection: tangential with innovative adapter

- Temperature range: -40 to +70°C

Special features:

- Best uniform warm water distribution by full cone spray

- Low pressure drop – no baffle inside

- Clogging free – no baffle inside

- Low spray height

- Mechanical connection nozzle – pipe (now screws, no clue, etc.)

- Own manufacturing

Design is patent property from CTS.

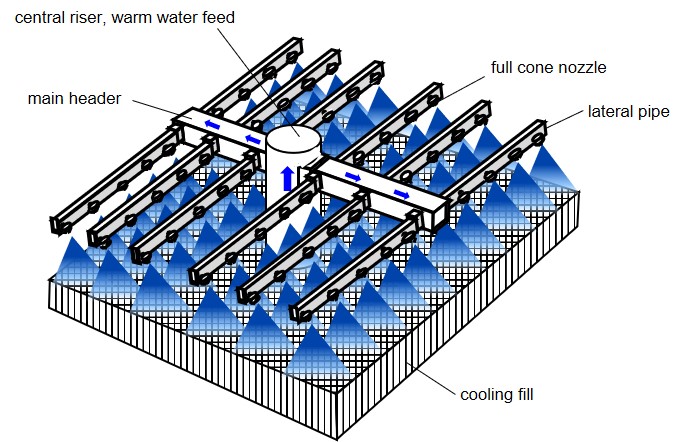

Water Distribution (WD)

Special features:

- Optimized spray by tangential-full cone nozzle

- Uniform total water flow distribution

- Central riser with uniform water supply

- Central pipe riser serves as approved pillar of the central machine unit

- Rectangular, stable FRP pipes

- Large span of pipes – less supports needed

Summarized features:

- Best warm water distribution in cooling towers

- Minimal nozzle pressure for WD needed

- Clogging free & very stable

- Taylor-made design and workshop adjustments

Design is patent property from CTS

Drift Eliminator – installed in natural draft cooling tower

Data:

- Type: TS 40 & TS 50 – lamella type

- Material: PP / PVC

- Material thickness: 1 to 1.2 mm

- Spacing: 40 / 50 mm

- Length x width x height: 2,400 mm x 600 mm x 224 mm

- Connection: mechanical (no spacers, no glue)

- drift loss: 0.0005 / 0.005 % (of cooling water flow rate)

- pressure drop: minimal (for example only 10 Pa at 3 m/s for TS 50)

- Temperature range: -40 °C to +55 °C (PVC) / 70 °C (PP)

- Fire retardant: B2 according to DIN 4201-1 or ASTM E 84, FSI < 25

Special features:

- High drift elimination rate

- Low air side pressure drop

- No additional spacers

- Easy cleaning & maintenance

- Small transport volume

- own manufacturing

Design is property of CTS with patent application

Axial Fan - Own Engineering

20 m diameter

Material

- hub: carbon steel with epoxy coating – up to sea water applications

- blades: FRP with leading edge protection against erosion

- coupling: cast iron or steel, coated

- connections: stainless steel or hot dip galvanized

- blade-hub connection: flange or U-bolt

Special features:

- Energy saving & low noise

- robust operational behaviour & highest reliability

- world-wide unique and long-term approved product

- Manufacturing based on original design

Geared motor as direct drive of axial fan

Special features:

- Motor + gear is axial mounted => geared motor

- Machine arranged below fan => easy maintenance access

- No drive shaft between gear box and outside located motor

- No drilling into fan stack (for drive shaft position)

Design is patent property from CTS

Fan stack – here with low noise Howden-SX-fan

Special features:

- Application always with energy saving diffuser

- Stable construction

- Optional with integrated noise attenuator

- With access hatch

- Own manufacturing

Design and technology are property from CTS

Fan stack with energy saving diffuser

Noise attenuators – installed in fan stack

Special features:

- Particularly corrosion-resistant

- Special lightweight construction